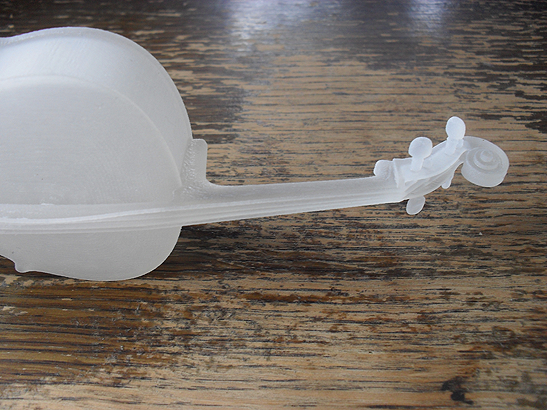

A cello was born

19/08/2011

Something very exciting happened today. My 3d printing finally arrived! If you want to see the pretty pictures scroll down to the bottom.

I ordered it from a site called shapeways, which is fast becoming the industry leader in 3d printing. The basic process is this: I make a 3d model on my computer, upload it to the website, which then checks for any errors or possible reasons why the printing wont work. If there are no issues then you choose a material to get it printed in, they print it, and then they send you it in a lovely package

Some info for people who might be interested:

- This one is made of a kind of plastic but shapeways offer a whole different host of materials including metals, glass and even full color sandstone.

- It is really light and barely weighs a thing.

- You pay for volume of material. In this way the cello was a good choice because most of it is hollow! Definitely hollow out your models before buying.

- There is a minimum wall thickness which varys per material (which is why I got this particular material). This is really worth paying attention to as I came into a lot of trouble with it for the cello. In general surface details print well, and fiddily bits print badly. This is why the strings are wonky. Unfortunately the upright was too thin at the top and broke in printing, but shapeways were good enough to give me a discount!

- Shapeways support is really friendly and awesome! This is pretty refreshing. They are happy to talk about the tools they use, the process, your orders, etc - and never do it in a patronising way.

- This print cost me around £50 (not including the discount). It is just over nine inches high. The material I was using was one of the mid-range to expensive ones. So for a model without strings and thin parts, you can get a lot cheaper.

- For this material the detail is really great! Is is also pretty strong and fairly flexible. Though the thin parts are delicate - the strings are only half a mm across.

If you have any more questions feel free to e-mail me or just head over to shapeways where there is a ton of info and I'm sure the support staff there will be happy to answer your questions.